World's first water wash flexo plate, Cosmolight®. Superior photopolymer technology produces a water-wash plate which is also durable to water-based ink

The CTP (computer-to-plate) technology is to be able to create higher and clearer reproduction of screen dots and letters.

.

Key Advantages:

- Lowest dot-gain and higher reproduction capability: Higher and clearer and reproduction of screen dots and letters.

- Solvent-free in the plate making process, toxic-free for the operator: This revolutionary plate eliminates the need to use toxic, environmentally damaging washout solvents, and allows processing by "Water".

- Reduction in the total cost: Consistent plate quality due to unnecessary to make a film-negative. Reduction in the personnel cost.

- Improvement of productivity: Shorter plate-making time due to the simplification. Laser ablation layer is able to washout with water.

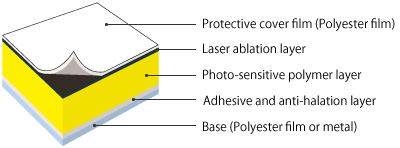

Structure of Plate:

Description:

Type |

Base film |

Hardness

(ShoreA) |

Thickness

(mm) |

Plaka Ebadı

(mm/inch) |

Key Advantages |

Main Application |

QS |

Polyester

0.125mm |

77

71 |

1.14

1.70 |

635×762/25"×30"

762×1016/30"×40"

900×1200/

35.4"×47.2" |

Press plate ready within one hour.

Good resistance to solvent ink, water ink

Usable on existing laser machines

|

Flexible

Packaging

Tag&Label

Envelope |

QH |

Polyester

0.125mm |

81

76 |

1.14

1.70 |

Plate-making Process:

Washout in plain tap water with a small amount of mild detergent. (Water temperature should be 40℃). Eliminate the use of dangerous hydrocarbon and hazardous water solvents.

All products are known throughout the world "ISO 9001" it is produced in the quality control system surveillance. |