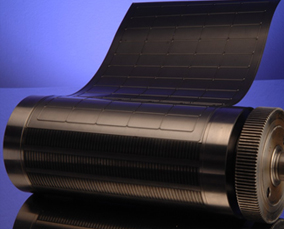

High-Tech product, in use not only in the printing industry but in various roll to roll production techniques, for converting wide range of materials

» Blade Heights

Although the production mostly based on 480micron and 780micron standard cylinder gap values, depending on the material to be cut various blade heights are used between 300µ to 1200µ.

» Cutting Angles

60 to 90 degree cutting angles are part of standard production. However, custom angles are optional and may be applied depending on a specific application.lir.

» Materials to be converted

Almost all materials used in printing, electronics, packaging, health industries can be converted. Materials which are coated, vellum paper, various types of cardboard, synthetic films, PP, PE, PVC, Tyvek, polyester, etc. are among very common applications.

» Applications

Self-adhesive labels, IML, embossing, folding cartons, envelopes, security applications, flexible packaging, printed electronics and circuit boards, braille and male-female applications.

» Multi-Height & Embossing

Ability to make a single die with 12 different heights, angles and

functions. Emboss and cut with a single die.Please refer our AED & EBD Pages for further information.

» Multi Function

A combination of different functions, including partial cut, slit, through cut, embossing, punching, perforation, slit-over-perforation and micro-perforation can be put on one single die.

» Flexible Die Types

- HTD (High-Tech Steel Flexible Die)

- HTD-X (Developed for Special MaterialsDeveloped for Special Materials)

- HTD-B (Developed for Box Making, Male/Female Set of Flexible Dies)

- HTD-O (Developed for Offset Presses)

- HTD-E (Developed for Embossing and Braille applications)

|

|